Smart automatic handing solution system

Smart automatic handing solution system

Current Location:

Current Location:

Traditional method: the user uses a manually driven electric forklift to transport the goods on site, and forks the power distribution cabinet to the designated location. On the way, two people are required to operate, one person drives the forklift, and one person needs to manually bind and fix the goods, resulting in irregular placement of goods and chaotic information management. , low operating efficiency (as shown in Figure 1)

Solution: Due to the complicated on-site operation environment of the user, the large volume of the cargo, the instability of the operation, and the irregular size of the pallet, etc., the requirements for the reliability, safety, and stability of the AGV are higher. The company's technology center is located in the standard forklift On the basis of the car body, customized holding fixtures are added, and a dual-coordinate counterweight AGV forklift is developed, which can carry 2000KG of goods. The shifter realizes position correction, solves the error problem in the process of stacking goods, is equipped with a multi-line laser navigation system, optimizes the walking path of AGV, improves the secondary positioning accuracy under the combined function of the fork, and realizes the characteristics of complex scenes and irregular goods. The intelligent handling solution under.

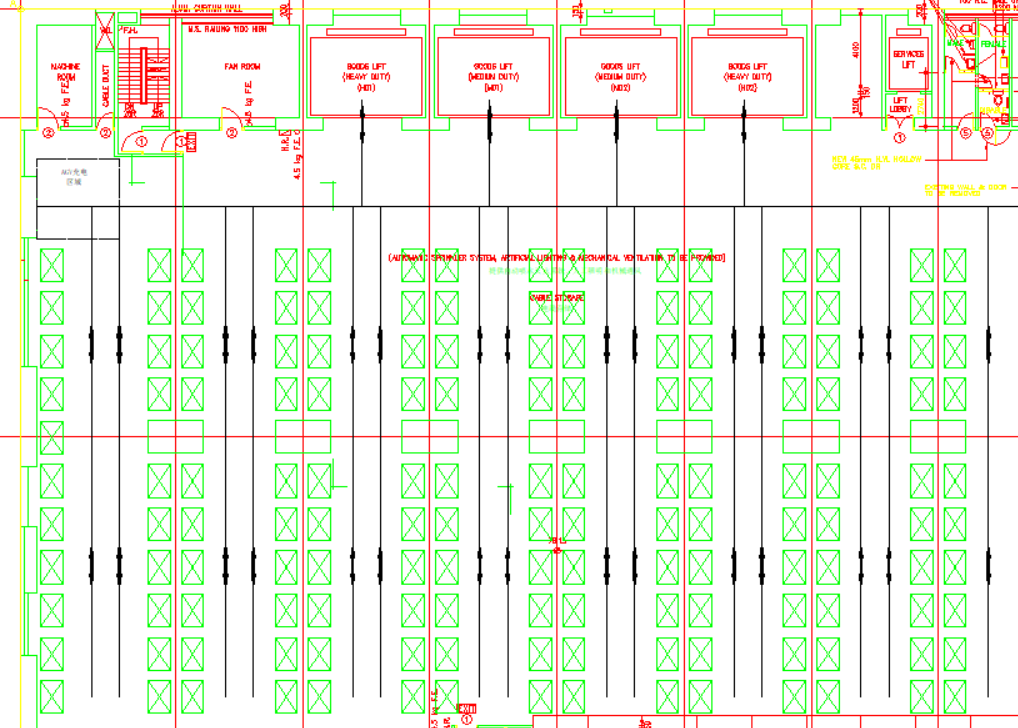

Inbound and outbound process: WMS sends out the warehouse-in task, the dispatching system independently developed by Yufeng controls the elevator to open the door, and sends a pick-up signal to the vehicle system, and the vehicle-controlled AGV picks up the goods from No. 1 elevator (a total of 4) and puts them into the warehouse area , to complete the storage; out of the warehouse, the AGV picks up the goods from the warehouse area and puts them into the No. 1 elevator, and the AGV moving action is completed (as shown in Figure 2).