Current Location:

Current Location:

Functional Solutions

Functional Solutions

The raw material/finished product warehouse is mainly composed of two parts: warehousing and palletizing, and the raw materials and finished products are stored in batches in units of pallets. The warehouse is seamlessly connected with the upstream processing line/downstream packaging line through the conveying system. Usually, the second floor enters the warehouse, the first floor leaves the warehouse, and the outside of the warehouse connects with the truck through the platform.

Conveying equipment includes chain conveyors, roller conveyors, transfer machines, hoists, AGVs, ground cattle working machines, RGVs, etc., which are widely used in the field of production logistics, such as workshop conveyor lines, online packaging lines, automobile assembly lines, etc.

In the automated three-dimensional warehouse system, the conveying system is the channel and bridge connecting the production site, the operation area and the storage area. It has the advantages of high automation, high continuous operation efficiency, low maintenance cost, and convenience.

Plate chain conveyor series

The plate chain conveyor is suitable for heavy-duty conveying of irregularly shaped items. The chain is made of hollow large rollers with attachment chains, and the attachments of the synchronous chains on both sides are connected with plate-shaped members to form a continuous flat plate in the conveying direction, so the operation is stable.

Roller conveyor series

The roller conveyor is suitable for conveying all kinds of boxes, bags, pallets and other items. Bulk materials, small items or irregular items need to be transported on pallets or in turnover boxes. It can transport a single piece of heavy material, or bear a large impact load, and the roller lines are easy to connect and filter. Multiple roller lines and other conveyors or special planes can be used to form a complex logistics delivery system to complete various aspects. Craft needs. The accumulation and conveying of materials can be realized by using accumulation rollers.

Hanging Conveyor Series

It has the functions of lifting, transportation, storage, etc., and can meet the requirements of various processing and assembly procedures. Widely used in automobiles, motorcycles, light industrial appliances, food, postal and other industries.

Reliable, fast and efficient order processing depends on high-throughput sortation systems, which are at the heart of modern distribution centers. Anhui Yufeng provides comprehensive linear and circular conveying and sorting systems guided by advanced controls and software that optimize warehouse operations and increase supply chain visibility.

Advantages of Yufeng sorting system:

■ Provide consumers with economical and efficient commodity flow;

■ Reduce labor costs through fast and accurate automation;

■ Increased production capacity for manufacturing and distribution;

■ Provides a high level of accountability to accurately track material;

■ Integrate with the latest supply chain technologies;

Anhui Yufeng provides a palletizing solution that recognizes marked objects through sensors and transfers them to designated locations for orderly placement, realizing the functions of intelligent classification, loading and unloading, and handling. The intelligent palletizing system has strong adaptability, and it can handle different types of products as long as the gripper is replaced. It occupies a small area, has a large operating range, and can handle multiple production lines at the same time.

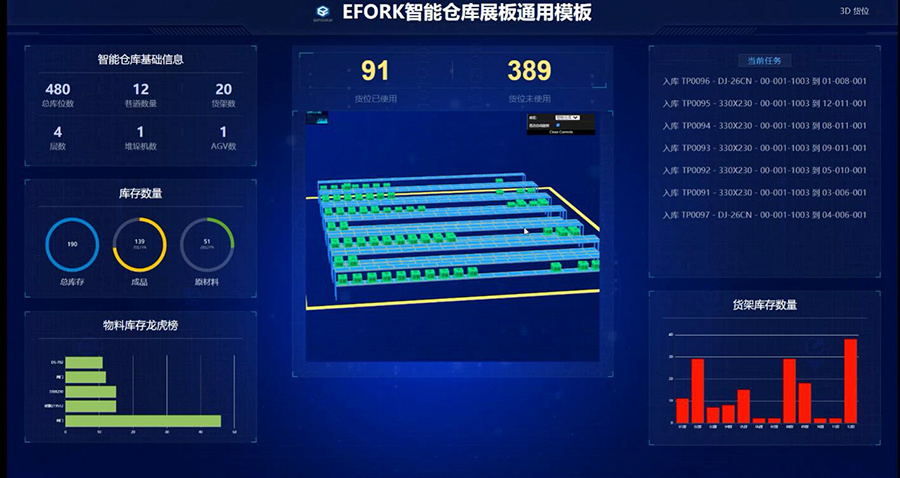

The intelligent handling platform is compatible Warehouse management system (WMS), manufacturing execution system (MES), enterprise resource planning system (ERP), warehouse control system software (WCS), and IO execution system meet the personalized requirements of various industries.

Industry Solutions

Industry Solutions

As a semiconductor company with a relatively high degree of informatization and automation, it is facing pressure from fierce market competition and rising labor costs. It is increasingly becoming a strong demand for semiconductor companies to accelerate automation and intelligent upgrades, and to better reduce costs and increase efficiency.

Recently, Yufeng Intelligent has carried out intelligent three-dimensional storage transformation for the existing warehouses of users in the semiconductor industry. With rich on-site experience and excellent product performance, the Yufeng Intelligent project team provides customers with overall solutions based on customer requirements and existing equipment and processes. The solution adopts the model of an intelligent system combined with the hardware in the warehouse area, with lower operating costs, higher operating efficiency, and better management methods to realize the storage, picking, verification, distribution, and delivery of materials from the warehouse to the production line. Intelligent operation mode of a series of links.

At present, the production equipment of large pharmaceutical production enterprises has basically realized automation, and a large number of automatic three-dimensional warehouses are used. In the field of pharmaceutical circulation, with the continuous deepening of my country's medical system reform, the separation of medicines, OTC drugs (over-the-counter drugs) and prescription drugs has brought about changes in the operation mode of the pharmaceutical distribution industry. Many pharmaceutical distribution companies are actively Explore and build your own pharmaceutical distribution logistics system. From the logistics system of raw materials, auxiliary materials, packaging materials, semi-finished products, finished products, and spare parts of pharmaceutical production enterprises to the logistics distribution center of pharmaceutical distribution enterprises, automatic three-dimensional warehouses are involved.

Manufacturing has always been the industry most affected by human factors. In recent years, the labor cost of factories has been increasing, work efficiency is difficult to guarantee, and production capacity has fallen into a bottleneck, which has brought huge challenges to the growth of the global manufacturing industry. Secondly, there is a lack of timely and efficient means of information exchange between upstream and downstream, and rhythm differences and pauses due to logistics waiting are also one of the factors leading to low industrial efficiency. The information isolation between different software systems in the factory also makes it difficult for the entire production line to synchronize information during the work process. Various problems have forced the manufacturing industry to accelerate its transformation from "labor-intensive" to "technology-intensive". It has become an inevitable trend to upgrade traditional warehouses to intelligent warehousing. Anhui Yufeng Intelligent Technology Co., Ltd., an "expert" in intelligent warehousing customization, can "tailor-made" intelligent warehousing solutions according to customer needs and pain points in work to realize warehouse management. "Cost reduction and efficiency increase" of work.

According to customer requirements and industry characteristics, it mainly provides intelligent power meter automation logistics system solutions for customers in the power industry. Solutions include automated three-dimensional warehouses and logistics delivery systems. The automated three-dimensional warehouse includes three-dimensional shelves, stackers, size detection barcode reading systems, communication systems, automatic control systems, computer monitoring systems, computer management systems and other auxiliary equipment, mainly used for automatic storage of measuring instruments and electricity information collection terminals . The logistics conveying system is used for automatic packing (unpacking) of measuring instruments and electricity collection terminals, automatic handling, automatic inventory, automatic storage and storage, and automatic positioning. It mainly serves the metering centers of State Grid and China Southern Power Grid.

Tobacco companies generally have many companies in cities under their jurisdiction, and their logistics resources are scattered, making it difficult to form efficient and systematic management. Anhui Yufeng started from the actual situation of the tobacco company and combined with the advanced logistics management concept, professionally formulated a set of modern logistics information system solutions for the tobacco industry, including sorting management system, warehouse management system, transportation management system, logistics information system, etc. . This tobacco industry solution can solve the problems of manual sorting and multi-level distribution, improve sorting efficiency, ensure refined management of cigarettes, reduce distribution level, improve management level, and achieve a leading domestic logistics information system.